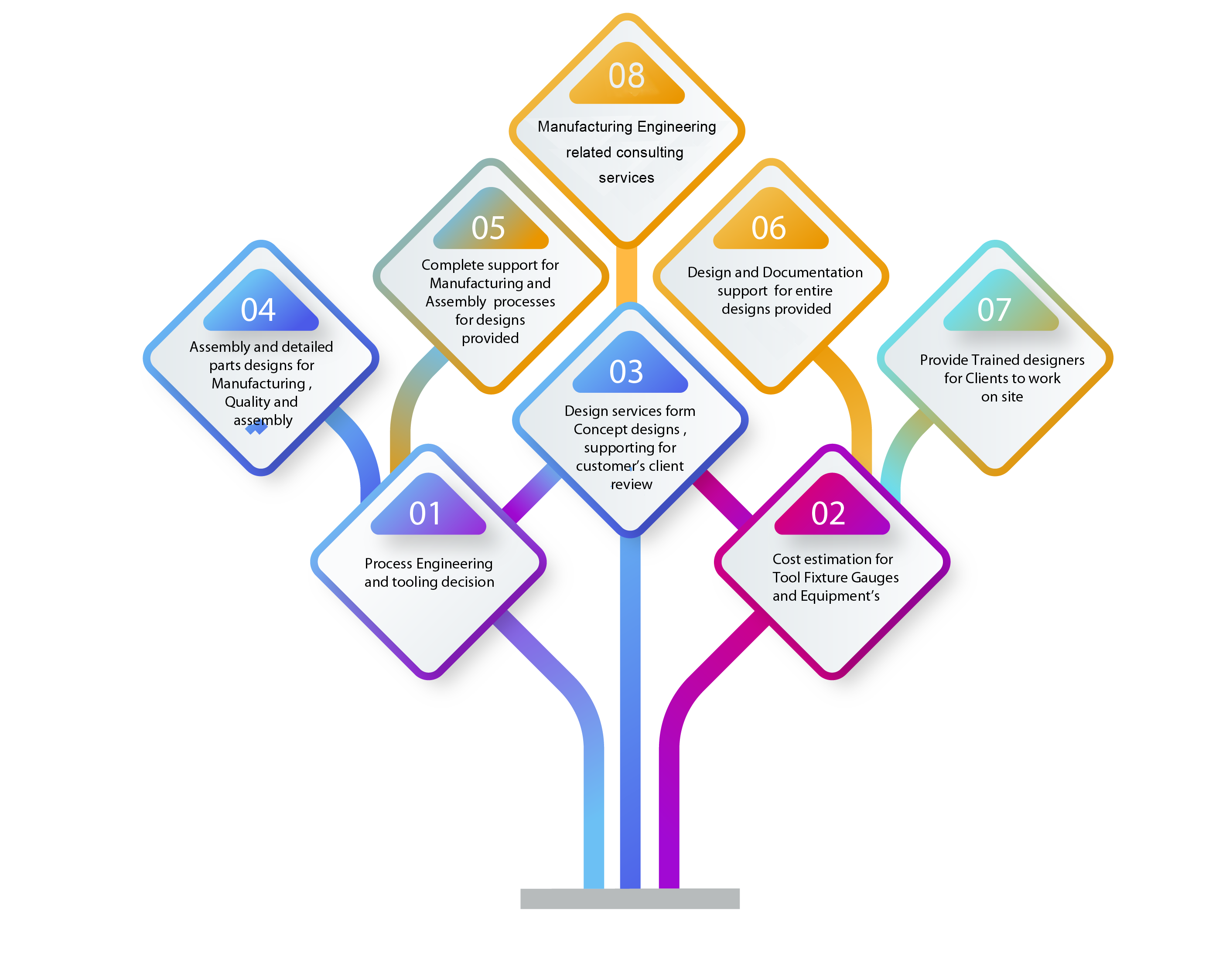

Kale Tool Designers (KTD) is established to provide Process engineering , Tool fixtures Gauges and Equipment’s Manufacturing Design services for all such industries.

Mr. Ajit Kale , who has worked in Manufacturing Engineering domain in Automotive OEM’s and Many world class tooling service provider and Tire 2 Companies at Senior level .

First time right was the buss word for Mr. Kale , today we are practicing the same.

We always Focus on Customer Needs for Budgeted Price .

Apart from Hands on experience in manufacturing , He has fully updated and integrated in latest design tools and practices.

We have started in 2014 and now focusing more in tool designing services for you.

We also train fresh or experience engineer in manufacturing and Design practices

Kale Tool Designers

Services

More reason to go with us...

-

Customized Solutions:

Highlight your ability to create tailor-made tool designs that meet the unique needs and specifications of each client. Emphasize that you don't offer one-size-fits-all solutions. -

Expertise in Multiple Industries:

If your tool design services cater to various industries (automotive, aerospace, medical, etc.), showcase your expertise and experience in each of these sectors, demonstrating versatility. -

Cutting-Edge Technology:

If you use advanced software, automation, or 3D modelling techniques in your tool design process, emphasize how these technologies enhance precision and efficiency. -

Rapid Prototyping:

If you offer fast prototyping and iteration of tool designs, stress how this reduces time-to-market for your clients' Services. -

Cost-Effective Solutions:

If your designs are not only high-quality but also cost-effective in terms of manufacturing and maintenance, make this a prominent USP.

-

Collaborative Approach:

Highlight your commitment to working closely with clients throughout the design process, ensuring their input and feedback are incorporated into the final design. -

Proven Track Record:

Showcase successful projects or case studies where your tool designs have led to significant improvements in productivity, quality, or cost savings for clients. -

Quality Assurance:

Stress your rigorous quality control processes and the steps you take to ensure that every tool design meets or exceeds industry standards. -

On-Time Delivery:

If you consistently deliver projects on time or even ahead of schedule, make this a key selling point.

Key Aspects About Kale Tool Design Services

Kale Tool design services specialize in the provision designs for customised tools and equipment for various industries. These tools are essential for manufacturing, production, and other processes. Here are some key Technological aspects of Kale tool design services:

-

Custom Tool Design:

Kale Tool Designers create custom tools tailored to the specific needs and requirements of their clients. These tools can range from simple hand tools to complex machinery. -

Productivity Enhancement:

Kale Tool Designers aim to improve productivity and efficiency in manufacturing and production processes. They design tools that can perform tasks faster, with higher precision, and at a reduced cost. -

Manufacturability Analysis:

Kale Tool Designers assess the manufacturability of a product and design tools that can be used in the most cost-effective and efficient manner during production. -

Materials Selection:

Kale Tool Designers select appropriate materials for tool construction, considering factors such as durability, wear resistance, and the demands of the application. -

CAD Modelling:

Computer-Aided Design (CAD) software are used in Kale Tool Designers to create detailed 2D and 3D models of the tools. These models serve for manufacturing. -

Prototyping:

Before final production, Kale Tool Designers often advise to make prototypes to test and refine the design. This helps identify any issues or areas for improvement. -

Tolerance Analysis:

Kale Tool Designers ensure that the tools they create meet tight tolerance requirements to maintain quality and precision in manufacturing processes.

-

Tooling for Specific Industries:

Kale Tool Designers are specialized in various industries, such as automotive, aerospace, electronics, and more. Each industry may have unique tooling needs. -

Cost Optimization:

Kale Tool Designers work to balance the cost of tool production with the benefits offered in terms of increased efficiency and quality. We aim to provide cost-effective solutions. -

Maintenance and Repair Tools:

Kale Tool Designers also create tools and equipment for maintaining and repairing machinery and equipment used in various industries. -

Safety Considerations:

Safety is a critical aspect of Kale Tool Designers we ensure that tools are safe to use and comply with relevant safety standards. -

Tooling Documentation:

Kale Tool Designers pays attention to comprehensive documentation, including design drawings and specifications, is provided to clients to aid in manufacturing and maintenance. -

Collaboration:

Kale Tool Designers often collaborate with engineers, manufacturers, and clients to ensure that the tools meet the desired specifications and requirements. -

Quality Control:

Quality control measures are integrated into our design process to ensure that the tools meet quality standards.